ansi z97glass impact test lab|ansi 97 vs 2406.5 : importing The ANSI Z97 Accredited Standards Committee (“ASC”) and its Secretariat, currently the Glazing Industry Secretariat Committee, have developed this recommended safety .

web20 de fev. de 2024 · yuzu Emulator GAME. yuzu is an emulator for Android, enabling you to play your favorite hybrid-console's games on your phone! Features include: The yuzu app does not include any games, or copyrighted system files. You are legally required to dump your games, keys, and firmware files to use with yuzu. The yuzu app is not affiliated, .

{plog:ftitle_list}

18 de jul. de 2020 · Watch full episodes of Power Rangers Super Megaforce now streaming on NETFLIX.Subscribe for More Power Rangers: http://www.youtube.com/powerrangersofficial?s.

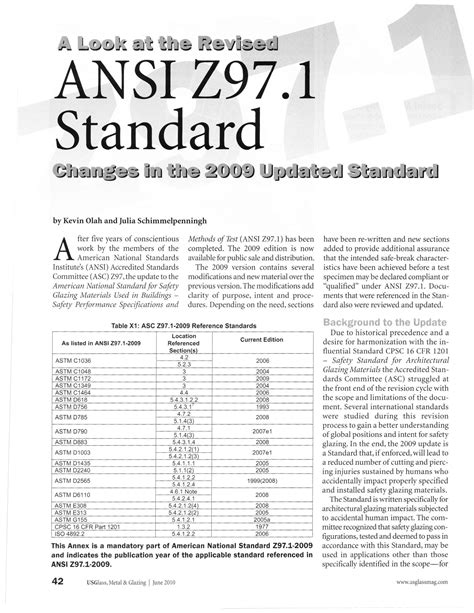

This Guidance document is to help further define and provide additional information on SGCCs “Production Testing” requirements. Note: Where ANSI or ASTM test methods are referenced .Test Procedure: Per Table 1 (Grouping of Tests for Safety Glazing Materials) of ANSI Z97.1, laminated glazing and organic coated glass shall meet the requirements of Impact, Thermal, .IMPACT TESTING ON SAFETY GLAZING MATERIAL. Rendered to: Paul Neumann 3M Company – Renewable Energy Division Building 235-3D-02 St. Paul, Minnesota 55114-1000. .

The ANSI Z97.1-2015 impact test rating includes the window film’s ability to hold glass fragments when impacted. When comparing 3M films to competitive products, be sure to compare results .

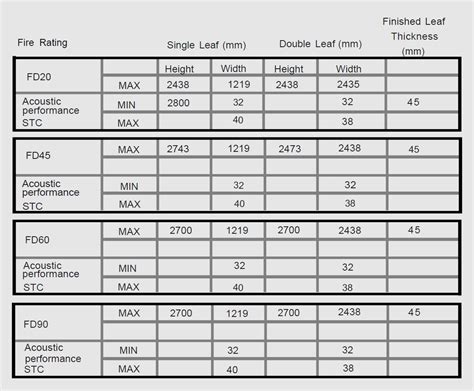

When selecting products, multifunctional glazing may be needed to fulfill the applicable codes. The glazing should be tested for all required functions such as fire resistance, impact .The ANSI Z97 Accredited Standards Committee (“ASC”) and its Secretariat, currently the Glazing Industry Secretariat Committee, have developed this recommended safety . The ANSI Z97.1-2015 (R2020) standard sets specifications and testing methods for safety glazing materials in building and architectural applications. These glazing materials are .

This standard establishes the specifications and methods of test for the safety properties of safety glazing materials (glazing materials designed to promote safety and reduce the likelihood of cutting and piercing injuries when the .Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test ANSI Z97.1 - 2015 Published by Glazing Industry Secretariat CommitteeIMPACT TESTING ON TEMPERED TRANSPARENT SAFETY GLAZING MATERIAL REPORT NUMBER I3147.01-119-37 TEST DATE(S) . New York to perform safety glazing impact testing in accordance with ANSI Z97.1, CAN/CGSB 12.1, and CPSC 16 CFR 1201 on their tempered transparent glass. . TEST RESULTS Lab Temperature: 69°F Duration of Pre-Conditioning @ .Boil Test | SS341:2001(2012) Impact Test | ANSI Z97.1-2004; Anti-Burglary Test | BS EN 356:2000; Surface Burning Characteristics Test | ASTM E84-23; Fire Test | BS 476 Part 7 1997; Adhesion Test | ISO 2409:2013; Solvent Resistance .

To ANSI Z97.1: 2009 for Glass Safety Test Consultant : JAS (Inspection & Testing) Ltd. Report Ref. : J3473-R12AN-161019 (ANSI) Manufacturer : DongGuan Jeff Glass Tech Co., Ltd. . 25+25mm : Impact Test - Comply to Class A No. of Specimens Tested : 8 nos. for each thickness Performance : Glass did not break Date of Test : 18th October 2016 .

intertek z97.1 pdf

F1093.02-119-37 Page 2 of 5 . Calibration: The test rig was last calibrated in accordance with Annex B of EN 12600 on 03/27/15, per EN 12600 B.4, the calibration shall be in effect for three years. Test Results: Ultra Night Vision S25 (Film-Side) Impact While the ASC Z97 and GISC administer the process in accordance with ANSI-established rules designed to promote fairness in the development of consensus, neither the ASC Z97 nor GISC independently test, evaluate, or verify the accuracy of any information or the soundness of any judgments contained within the standard document, ANSI Z97.1.

compression spring load testing machine

A: Once samples are received at the laboratory, testing can take between 1 and 3 weeks, please contact the laboratory of your choice from the SGCC approved laboratory list to inquire as to time frame for your job. Q: What do I do once I receive my reports from the test lab? A: Provide those test reports to SGCC by emailing them to [email protected] TESTING ON TEMPERED TRANSPARENT SAFETY GLAZING MATERIAL REPORT NUMBER J4719.04-119-37 TEST DATE(S) . Canada to perform safety glazing impact testing in accordance with ANSI Z97.1, CAN/CGSB 12.1, and CPSC 16 CFR 1201 on their tempered transparent g lass. . TEST RESULTS Lab Temperature: 70°F Duration of Pre-Conditioning .Lab Temperature: 75°F Size Classification: Unlimited . . 85ºF: 48 Hours . Specimen Size: 34" wide by 76" high / Impact test . All test specimens were destroyed by test or by our personnel and have been disposed of as trash. Sample ID: Safety S40 . ANSI Z97.1-2009 0.226 18 31-1/2" x 1-1/4" opening – 12 93 Pass *3 ; ANSI Z97.1-2009 / CPSC .

Safety Glazing Testing per ANSI Z97.1-2015 (CPSC 16 CFR 1201) 3M™ Scotchshield™ Safety & Security Window Film 3M™ Safety & Security Window Film Ultra S800 Ultra Prestige Ultra Night Vision Safety S140 Safety S80 Safety S70 / S70X Safety S40 Class A (Category II ) 400 lbf impact Pass Pass Pass Pass Pass Class B (Category I ) 150 lbf impactAn industry recognized “swing bag” test was conducted under controlled lab conditions, based on the protocol outlined in ANSI Standard Z97.1-2004. This protocol considers the impact loading created by a 100-lb (45.4 kg) shot bag, dropped from various heights. Because the intent of the test was to EXCEED the force needed toIn the US, currently, safety glass is described in CPSC 16 CFR 1201 and/or ANSI Z97.1. In Europe, currently the standard describing safety glass is EN 12600 – called, Pendulum test- Impact test method and classification for glass, to simulate the impact of a human body. Other regions of the world may have different standards for safety glass.

intertek z97.1 certification

Test - As a minimum, testing shall occur on the first of each product thickness per shift . Additional testing may be appropriate. Laminated – ASTM F3007. 1. and/or ANSI Z97.1 Impactor Test - During regular production periods, a minimum sample collection shall be performed weekly , and actual testing occur at least monthly. Sample collection .impact test (Class A); a 150 foot-pound impact test (Class B); and a 100 foot-pound impact test (Class C) for fire-resistant wired glass. The NPR did not propose to modify the impact categories for testing. The CPSC standard provides only two impact categories, 150 foot-pound impact test (Category I) and 400 foot-pound impact test (Category II .

HaanGlas VIG Passed ANSI Z97.1 impact test. HaanGlas tempered vacuum insulating glass,passed ANSI Z97.1 test in Intertek,show end users the safety performance and unlimited application in windows,doors and glass facades. ANSI Z97.1 is the American National Standard for Safety Glazing Materials for Buildings.ANSI ANSI ANSI ANSI Z ANSI ANSI ANSI zqa7 1 zqa7 1 707 1 Inclivicll.lül Individual Individua 1 Individual 1 Individl-lül 1 Individu¿ Individual Member Men-I her (Observer Member Mernb+:žl- Arch ancl Testing Inc Inú. ALIas Malarial I Glass Darynnt Glass an-linnrng Prnclucts E-vûllik Glass Asracuticrl North Amerii:c Gl,larcliall Corp.

The ANSI Z 97.1 standard is most commonly used for residential applications while the CPSC CFR 1201 is more often found in commercial applications for glazing. The ANSI Z 97.1 standard usually requires a 100- and 150-foot-pound .

1.2 This test method is intended for use as an in-plant quality control test to evaluate the impact performance of laminated flat glass when a 2.3 kg, 83 mm diameter smooth solid steel ball is dropped from a user selected height. 1.3 This test method is not a substitute for safety glazing test requirements of ANSI Z97.1 or CPSC 16 CFR 1201. The Accredited Standards Committee (ASC) seeks to update ANSI Z97.1-2015 (R2020), Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test. The ANSI Z97.1-2015 (R2020) standard sets specifications and testing methods for safety glazing materials in building and architectural applications.

Testing for safety glazing attempts to recreate the accidental human impact by using a pendulum with a soft body impactor. ANSI Z97.1 and EN 12600 are two common test methods for this safety glazing. [2, 3] The ANSI Z97.1 pendulum test uses a leather punching bag as the impactor.date and place where CPSC testing was conducted, and it must identify the product and the federal safety standard with which it complies. When certification of compliance depends upon testing by a third-party laboratory, the certification must also identify that laboratory by name, mailing address, and telephone number.

The Accredited Standards Committee (ASC) seeks to update ANSI Z97.1-2015 (R2020), Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test. The ANSI Z97.1-2015 (R2020) standard sets specifications and testing methods for safety glazing materials in building and architectural applications.

ansi z97.1

On January 13, 2016, the ANSI Z97 Accredited Standards Committee released a technical interpretation to clarify the impact test specimen evaluation criteria for diverse types of safety glazings. It reads, “There is no reference to vacuum insulating glass (VIG) in ANSI Z97. 1-2015. . (VIG) in ANSI Z97. 1-2015. It is unclear how to test .The kinetic energy impact loading shall comply with ANSI Z97.1 using a 400 foot-pound (542 N) energy impact. The safety requirements of the impact test shall be judged to have been satisfactorily met if breakage does not occur or numerous cracks and fissures occur but no shear or opening through which a 3-inch (76 mm) diameter sphere may freely .

Impact Safety Testing (Tempered, laminated, organic coated and plastic products): ANSI Z97.1, CPSC 16CFR 1201; . Safety Glazing Testing: ANSI Z97.1, CPSC 16 CFR 1201, UBC 24-2, UL 9; Motor Vehicle Glazing Testing: ANSI Z26.1; Windborne Debris .Shot Bag Impact Apparatus is built to meet GB9963,GB/T9963,ECE R43 and used to shot bag impact testing or pendulum testing glass. Standard: ANSI Z97.1-1984, ISO/DIS12542 1~12543-6:1997, AS/NZ S2208:1996, GB/T9962-1999

This standard establishes the specifications and methods of test for the safety properties of safety glazing materials (glazing materials designed to promote safety and to reduce or minimize the likelihood of cutting and piercing injuries when the glazing materials are broken by human contact) as used for all building and architectural purposes .

Impact • No change in irradiation for accelerated weathering from ANSI Z97.1 • Method A – Dry | Method B - Spray • Standardizes weathering and reporting • New products have target performance criteria • Compliant with SGCC requirements • Increase requests for exposure data – compliance • Update reference to the standard in

fabrication of helical spring load testing machine

fabrication of helical spring load testing machine pdf

Resultado da Uptodown App Store. Support. Download the APK of 91mobiles for Android for free. Compare prices on smartphones and other device in India.

ansi z97glass impact test lab|ansi 97 vs 2406.5